OG SERIES GENERATOR

Pressure swing adsorption

OXYGEN GENERATOR INTRODUCTION

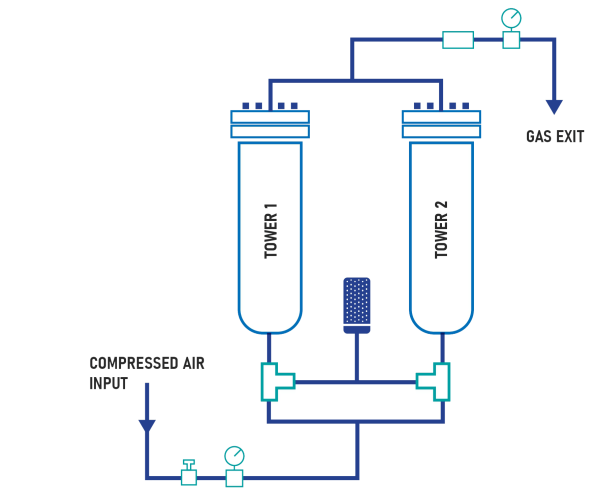

PSA oxygen generator is a machine producing oxygen by separating oxygen from air. It adopts the principle of PSA (pressure swing adsorption). Pressure swing adsorption processes rely on the fact that under pressure, gases tend to be attracted to solid surfaces, or “adsorbed”. The higher the pressure, the more gas is adsorbed; when the pressure is reduced, the gas is released, or desorbed.

PSA processes can be used to separate gases in a mixture because different gases tend to be attracted to different solid Surfaces. When air is passed under pressure through a vessel containing an adsorbent (zeolite molecular sieve) bed that attracts nitrogen more strongly than it attracts oxygen, part or all of the nitrogen will stay in the bed, and the gas coming out of the vessel will be enriched in oxygen. When the bed reaches the end of its capacity to adsorb nitrogen, it can be regenerated by reducing the pressure, thereby releasing the adsorbed nitrogen. It is then ready for another cycle of producing oxygen. In this way, high purity oxygen is produced

PSA TECHNOLOGY

BASIC STRUCTURE

A complete oxygen generator consists of: Air compressor, Air Treatment Circuit, Air Receivers, PSA oxygen generator, Oxygen Receiver, Super Charger Compressors and Medical Filtration.

*This photo is for explanation only, real machine structure will be based on flow rate and site space, etc

AIR COMPRESSOR

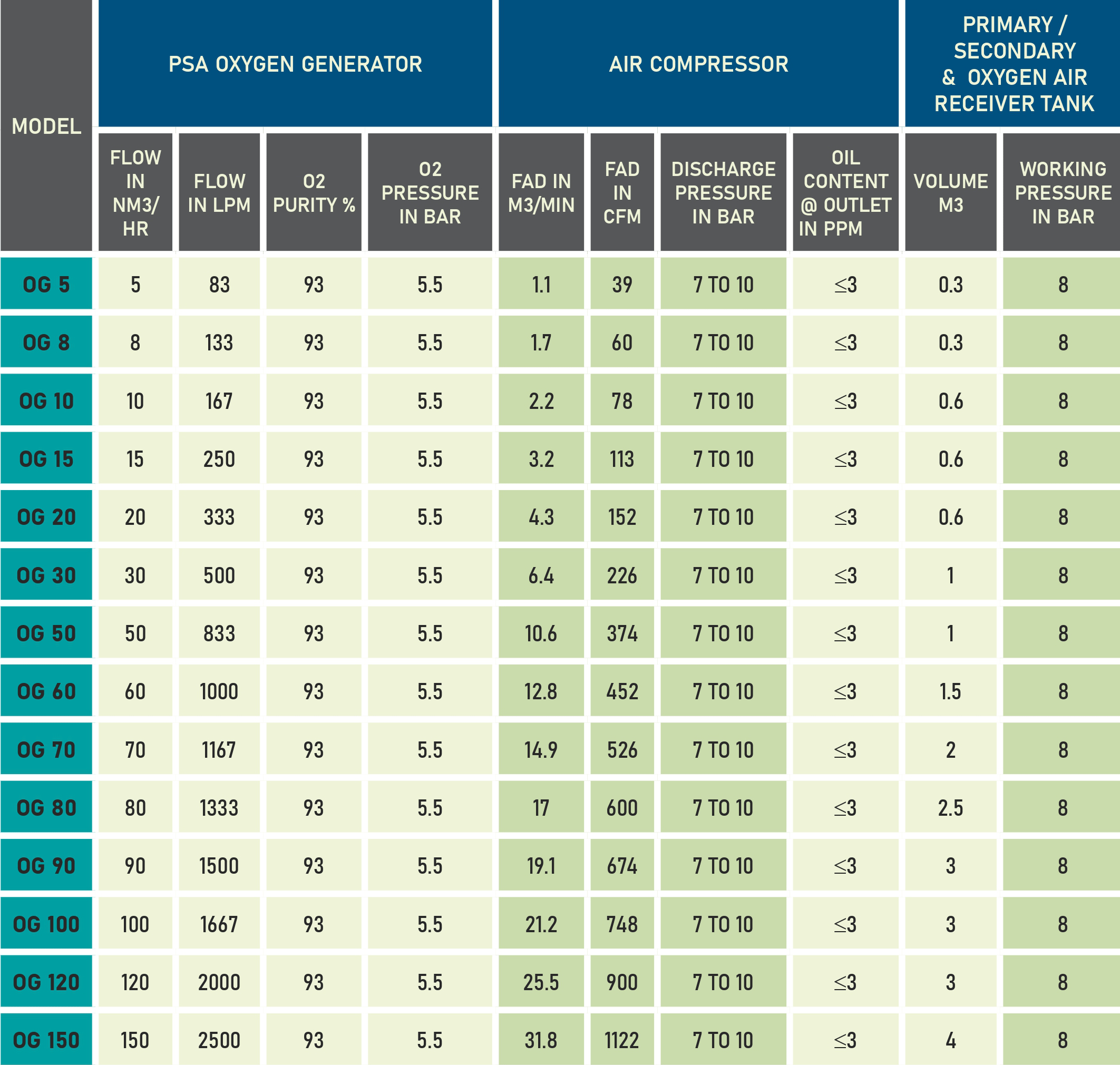

Air compressor provides compressed air source for the PSA oxygen generation part, the flow and pressure are to be decided by the desired oxygen flow rate, purity, outlet pressure. As it is the air source of whole system, the performance of air compressor has remarkable influence to the whole oxygen generator system.

AIR TREATMENT CIRCUIT

To get rid of water, oil, impurities in compressed air coming from the air compressor, providing clean, dry, oil-free compressed air for the PSA oxygen generation part. It includes 3 filters, 1 refrigerated dryer and 1 activated carbon oil remover. After treatment, dew point of compressed air can reach -20 degree (normal pressure), dust content is not larger than 0.01mg/m3, solid particles diameter is not larger than 0.01μ, oil mist content is not more than 0.003mg/m3.

PSA SEPARATION

It is the key part of whole system. In this part, the oxygen is separated from compressed air, sent to buffer tank as produced gas. Nitrogen, carbon dioxide, argon,etc are discharge from muffler as exhausted gases. The efficiency of this machine is mainly decided by adsorption tower structure, air distribution structure, molecular sieve performance, process flow, etc

PRODUCT DETAILS

HIGH RELIABILITY

Proven PSA technologies such as big flange structure, snowstorm filling, gas distribution system, gas speed control technology, unequal pressure balance system, etc make REINIGEN Gas oxygen generator more reliable.

EASY INSTALLATION

Skid structure, fully assembled and test qualified before delivery. When machine reaches site, with simple connection of power supply and gas pipeline, the machine is ready for operation. No need to disassemble and/or re-assembly at site.

MINIMIZED MAINTENANCE

After 8000 hours operation, simply replace the three filter elements and activated carbon for air treatment part, no other regular maintenance needed

LOW OPERATION COST

With REINIGEN LUFT technologies, producing same flow rate, same purity oxygen, smaller compressed air is needed, saving customer air compressor electricity consumption cost every day.