COMPRESSED AIR THREADED FILTERS

CLEANLUFT CLF SERIES

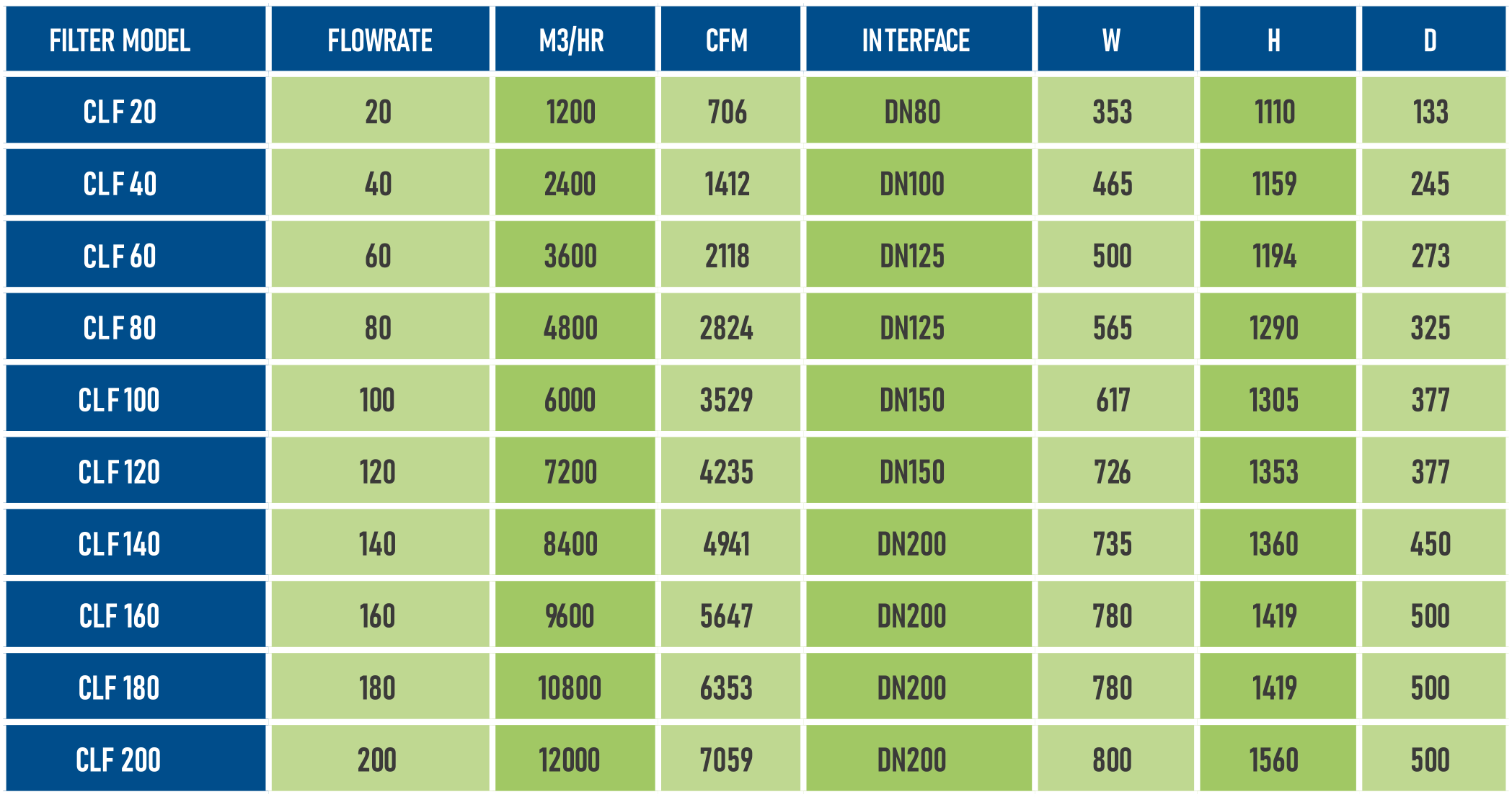

702 CFM - 7059 CFM

The Flanged precision filter has many characteristics such as high pollution capacity, corrosion resistance, good temperature resistance, large flow, easy to operate, long service life, and no fiber shedding

The innovative filter housing and filter element design achieve optimum flow characteristics at minimum pressure drop resulting in considerable cost savings throughout the entire operating lifetime of the filter element. Highly-efficient, borosilicate nanofibre media with a voids volume of 99 % ensures high dirt-holding capacity at constantly low differential pressure. This efficiency is supported by deep-pleating technology enabling 4.5 times more filtration surface area to be incorporated into the element, when compared with conventional filter elements. The filterhousing design has been designed for easy of maintenance: The deep-seated service-flange, supported by a pivoting hingejoint, enables element replacement to be undertaken by a single individual. The dished-bottom provides ample space to drain away liquids efficiently. These filters are equipped with a optional level sensing, electronic condensate drains from the tried and tested Zero Air loss drain KONDENSAT ID 54L series, characterized by their zero air-loss function and reliable drainage of even the largest amount of oil/ water condensate Multi – Layer different filtration materials are used to filter impurities in compressed air, including borosilicate layer, glass fiber layer, activated carbon fiber layer, multi – layer non – woven layer and stainless steel mesh layer. Through multi – layer filtration, the high quality compressed air without oil and impurity is achieved.

TECHNICAL DETAILS